Best Price guarantee

This commitment ensures you get the highest quality FIBCs at the most competitive rates, giving you peace of mind in your purchasing decisions.

Free Sample Guarantee

This guarantee is our way of ensuring that you are fully satisfied with the quality before making a Purchase.

Best quality guarantee

This guarantee reflects our dedication to providing you with reliable, durable, and superior FIBC solutions, giving U confidence in every purchase.

Big Bag

- Food Grade

- UV Treated

- Water Proof

- Large Loading Capacity

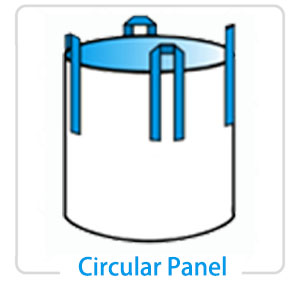

tubular FIBC Bulk Bag

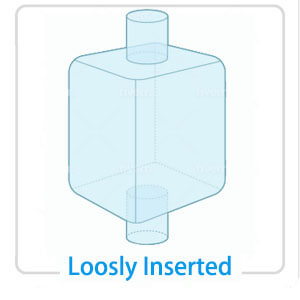

Tubular Body 4 Side 4 Loop FIBC Bag

Tubular fibc bag with 4 lifting Loop has no verticals seams, because it is woven with circular looms. most common construction type is a circular fabric on the body with a sewn square base. This guarantees more protection again humidity and much more efficient containment capacity for dusty and grainy materials.

MOQ

For plain Tubular FIBC, the MOQ is 500 pieces.

For Printing requirements, the MOQ is 1000 pieces.

Color Option

Customization Option

QinFeng Factory Direct, 24+ Years Experience, Professional Design, OEM/ODM

FIBC Characteristics

ACCESSORIES

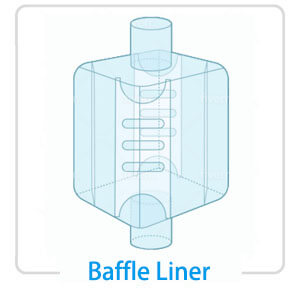

- Liner

- Customized printed logo up to 4 sides/3 colours

- Document pockets

- Dustproof seams with cord

- B-Lock or Velcro closing systems

CAPACITY

- 500kgs-2000kgs

SECURITY FACTOR

- 5:1 Single Trip

- 6:1 Multi Trip

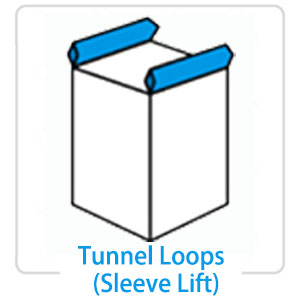

lIFTING STYLE

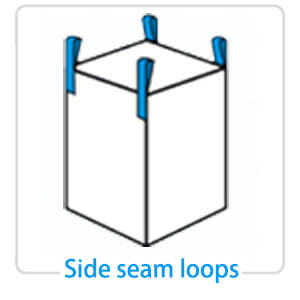

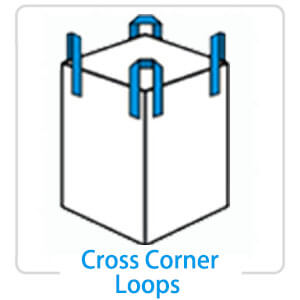

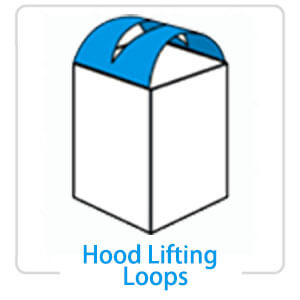

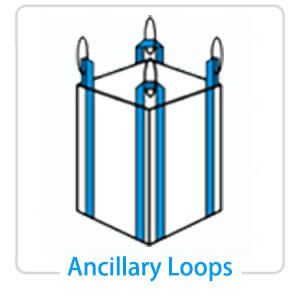

- 4 Cross Corner Loop

- Optional Stevedore Loop for easy lifting

BODY MATERIAL

- Tubular Fabric weight 140-225gr/m2

- Tubular Fabic with reinforced bands

- Minimum weight of coating 25gr/m2

- Maximum tubular fabric width 225cm

FABRIC

- Circular standard

- Coated circular

What are Tubular Bulk Bags?

Tubular bulk bags, a subset of Flexible Intermediate Bulk Containers (FIBC), are cylindrical in shape and crafted from woven polypropylene fabric. Unlike standard FIBCs, which are constructed from flat panels, these bags are made from a continuous tube of fabric, providing a seamless construction. This unique design enhances their strength and durability.

Features of Tubular Bulk Bags

- Seamless Construction: The tubular design eliminates side seams, reducing the risk of tearing and improving the overall structural integrity.

- Uniform Shape: The cylindrical shape ensures uniformity in dimensions, facilitating easier handling and stacking.

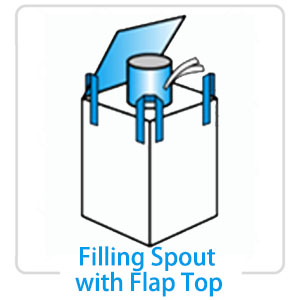

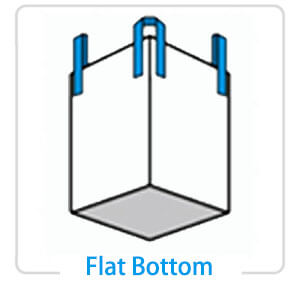

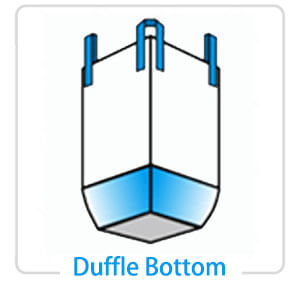

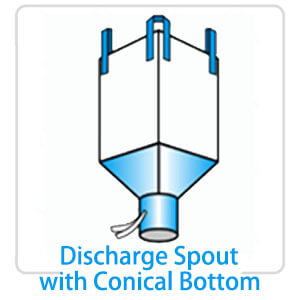

- Customizable Filling and Discharge Options: They can be fitted with various top and bottom options like spouts or flat panels, tailored to specific filling and discharge requirements.

- UV Stabilized: These bags are often UV stabilized, ensuring longevity and resistance to degradation when stored outdoors.

- High Safe Working Load (SWL): They are designed to safely hold a significant amount of weight, which varies based on the specifications of the bag.

Advantages of Using Tubular Bulk Bags

Tubular Bags have several advantages for various applications. With the cylindrical design there are no seams at the broad side of the bag. These bags are easier to make and are more cost-effective for purchase as well.

- Enhanced Strength and Safety: The seamless design offers added strength, making them safer for transporting and storing heavy materials.

- Versatility: Suitable for a wide range of materials, from fine powders to larger granules.

- Improved Storage Efficiency: Their uniform shape allows for optimal utilization of storage space.

- Eco-friendly Option: Reusable and recyclable, they align with sustainable practices in material handling.

- Cost-Effective: They provide an economical solution for bulk storage and transportation needs.

Applications of Tubular Bulk Bags

Tubular bulk bags are versatile and find applications in diverse industries. They are ideal for:

- Agriculture: Transporting and storing grains, seeds, and feed.

- Chemicals: Safe handling of powdered or granulated chemicals.

- Construction: Carrying sand, gravel, and other construction materials.

- Food Industry: Ideal for food-grade materials like sugar, salt, and flour.

- Pharmaceuticals: Used for bulk handling of pharmaceutical ingredients.

- Mining: Transporting minerals and other extracted materials

Specifications

Tubular Bags can efficiently carry materials weighing around 3,500 lb. When selecting tubular bulk bags, consider the following specifications:

- Dimensions: Tailored to your specific storage and transportation needs.

- Fabric Type: Options include coated or uncoated fabric, depending on the level of moisture protection required.

- SWL and Safety Factor: Depending on the weight of the materials to be stored or transported.

- Top and Bottom Design: Customizable for specific filling and discharge requirements.

- Certifications: Ensure they meet relevant industry standards and regulations.

Tubular bulk bags offer a reliable and efficient solution for bulk material handling. Their unique design and customizable features make them suitable for a wide range of industries, contributing to safer and more efficient operations. As always, it’s important to select the right specifications to match your specific needs.

Tubular bulk bags are an excellent choice when looking for durability, versatility, and efficiency in bulk material handling.

Find the best bulk bag for your product today!

What are the advantages of tubular bulk bags?

- Resistance at Low Temperatures

- Pharmaceutical and Food Grade.

- Release merchandise from the bag's bottom remotely, without removing the bag from the ground.

| Fabric | 100% Polypropylene (Laminated ) | Bag Size | 90x90x120cmH or 100x110x130cmH or Customized |

| Color | White,Black,Blue, green, or customized | Feature | Moisture Proof, Recyclable, Dustproof , Antistatic |

| Loading Capacity | 500kg-2000kg | SWL | 5:1 6:1 |

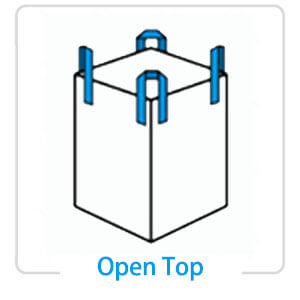

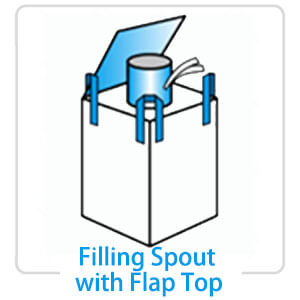

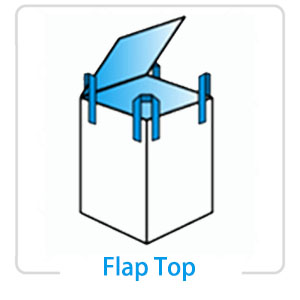

| Top | Full open/ Filling spout/ skirt or customized | Bottom | Flat bottom/Discharge spout/Full open/Closure |

| HS Code | 6305320000 | Application | Construction Agriculture, Chemical,Mining etc |

| Production Time | with 35-45days after payment | Packing | Bale, Pallet or Single Packing |

✺More Type of Bag ✺ More Type of Bag ✺ More Type of Bag ✺ More Type of Bag ✺

Duffle Top Flat Bottom

Spout Top Flat Bottom

Flap Top Flat Bottom

Stevedore Strap

Spout Top Spout Bottom

Spout Bottom Detail

Perimeter Belt with Stevedre Strap

Spout Top Flat Bottom

Spout Top wih Liner

Duffle Top Flat Bottom

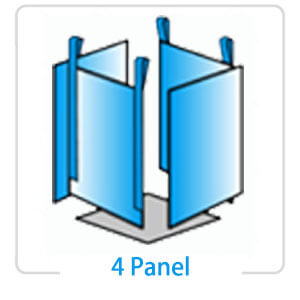

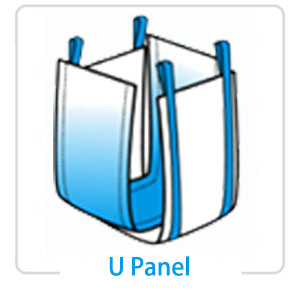

TYPE OF LINER

LINER ATTACHMENT OPTION

Why Are Our Clients So Vocal in Recommending Us to Others?

Certification Authority

At QinFeng, we prioritize excellence through rigorous standards. Our products are certified and tested by recognized third-party institutions such as ISO, SGS, and TUV. These certifications underscore our unwavering commitment to quality, safety, and performance.

Automated Production Line

Our automated production lines ensure the consistent quality and cost-effectiveness of our FIBC bag solutions. Utilizing advanced equipment and optimized manufacturing processes, we deliver maximum durability and reliability at the most competitive prices.

As CEO, I envision building a company you can always rely on as a trusted partner. We achieve this through an unyielding commitment to integrity, quality, service, and collaborative innovation.

Professional Knowledge Base

Our extensive knowledge base offers tailored solutions for any equipment or application challenges related to our FIBC bags. With a robust inventory and a world-class customer support team, we ensure prompt resolutions to meet your needs effectively. Rely on us for expert guidance and exceptional service as you optimize your material handling processes

Support OEM / ODM

we provide comprehensive OEM and ODM solutions tailored to your business needs. Whether you’re seeking high-quality FIBC bags as an OEM partner or customized branding options as an ODM client, we have the full capabilities to deliver exactly what you require. Trust us to help you achieve your goals with our expert services and quality products.

Excellent Warranty Policy

our products are manufactured under stringent ISO 9001:2015 quality controls, utilizing superior materials and advanced technology. With strict inspections and testing processes in place, we guarantee consistent quality and performance. Plus, we stand behind our products with an industry-leading 2-year warranty, ensuring your complete satisfaction and peace of mind

Proven and Trusted Millions of Times

At QinFeng Plastics, the notion of quality goes beyond a simple protocol. We regard it as a guiding principle that informs all of our decisions and actions. Flexible Intermediate Bulk Containers (FIBCs) require meticulous attention to detail, and we spare no effort to ensure that every product that departs our factory exemplifies excellence and dependability.

When our customers place their trust in our products, they require the reassurance that comes from our facility’s meticulously designed and implemented quality control protocols.

Thorough Inspection and Testing of Raw Materials

We believe that quality begins with the raw materials. Therefore, each shipment of raw materials we receive undergoes stringent inspection and testing. Using cutting-edge testing equipment, our specialists examine the consistency of material quality.

Quality inspection after product completion

Our dedication to quality extends to the very last stage of production. Before any product is shipped, it undergoes a thorough evaluation procedure. This includes a variety of tests that evaluate dimensions, tensile strength, and load capacity, among other characteristics.

Sampling inspection of products before shipment

Assuring precision, consistency, and, most importantly, maintaining the exceptional quality of our products is only possible thanks to the technological advances we’ve made in our quality control process.

NOTE:

On Time, Every Time How We Deliver

Timely delivery of our FIBC bags starts long before your order is placed. We proactively monitor material production cycles across various regions to accurately forecast demand, ensuring we have sufficient capacity and stock in place ahead of peak seasons. By collaborating with reliable shipping partners, we guarantee on-time delivery, meeting your tight deadlines with confidence. Trust Qinfeng to keep your operations running smoothly and efficiently.

Production Plan Time (1-3Days)

Once we receive your order, we will set up the production plan promptly; within 1 -3 days of finalizing the production plan, we will commence manufacturing your goods

Manufacturing Time (25-45Days)

Small quantities of orders will be produced with our stock base cloth, for special color requirements and large quantities of orders need from the drawing, weaving, cutting, sewing, quality inspection, packaging all processes

Packing Time (2-3Days)

Mass production of bulk bag completed, Bag are compressed in bales press,The results for neat and easy packing of bag. Then packed bulk bags are sent to storage room waiting to dispatch customer location

Shipping Time (3-30Days)

The shipping time will be different according to different destinations. We will follow up the whole process and assist customers in customs clearance.

Common Questions

Most Popular Questions.

FAQ section provides comprehensive information about TUBULAR FIBCs, helping customers understand their features, benefits, and usage.

A Tubular FIBC (Flexible Intermediate Bulk Container) is a type of bulk bag made from a continuous tube of fabric. Unlike standard FIBCs with multiple panels, TUBULAR FIBCs are constructed from a single piece of fabric, which provides enhanced strength and durability. They are ideal for storing and transporting a variety of bulk materials.

- Increased Strength: The continuous tube design provides superior strength and resistance to tearing and punctures.

- Reduced Seams: Fewer seams mean fewer points of potential failure, making these bags more reliable.

- Cost-Effective: The efficient use of fabric and reduced production complexity can lower costs.

- Customizable: They can be customized in size, strength, and fabric type to suit specific needs.

TUBULAR FIBCs are typically made from woven polypropylene (PP) or polyethylene (PE) fabrics. These materials are chosen for their durability, flexibility, and resistance to moisture and chemicals. For specialized applications, other materials or coatings can be used.

- Chemical: For transporting powders and granules.

- Construction: To handle aggregates, sand, and other building materials.

- Agricultural: For bulk grains, seeds, and fertilizers.

- Food Processing: To store and transport ingredients or products.

- Material Type: Consider the nature of the product being transported and its interaction with the bag material.

- Size and Capacity: Ensure the bag size and capacity meet your storage and handling requirements.

- Strength Requirements: Select a bag with the appropriate strength for your load.

- Custom Features: Think about additional features like liners, coatings, or special closures.

- Storage: Keep them in a dry, cool place away from direct sunlight and chemicals.

- Handling: Use proper equipment and techniques to avoid damage during loading and unloading. Avoid dragging or dropping the bags.

Yes, TUBULAR FIBCs can be reused if they are properly cleaned and maintained. However, their reusability depends on the material and the nature of the product they have contained. Always inspect the bags for any signs of damage before reuse.

Absolutely. TUBULAR FIBCs can be customized in terms of size, color, fabric type, and additional features like liners, coatings, or printing. Contact us to discuss your specific requirements and get a tailored solution.

Open Top Flat Bottom